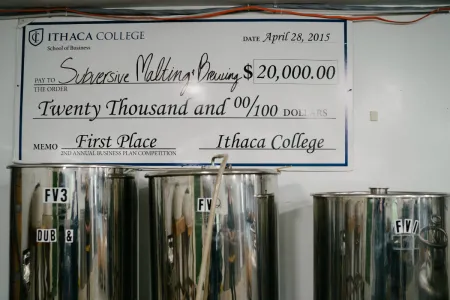

Four years ago, Ithaca College students Max Ocean ’15 and Zane Coffey ’15 entered the college’s Business Plan Competition with an audacious idea: to launch a brewery that would use all local ingredients and malt its own barley. Today, Subversive Malting & Brewing offers a diverse array of lagers and ales at its beer cafe in Catskill, New York, and is on the verge of expanding across the Hudson Valley.

At the height of the farm-to-table movement, Ocean and Coffey are betting that customers care just as much about where the ingredients in their beer come from as they do about the ingredients in their entree. That was the winning pitch they made to the business competition judges. “I think they saw the market opportunity that we saw,” Ocean says. “And we made some home brew and brought that in for samples,” Coffey adds. “That was a fun thing.”

And while some may think that local breweries necessarily use local ingredients, that’s not usually the case. Ocean and Coffey say that ingredients like hops are often sourced from farms thousands of miles away, and sometimes even overseas. They chafe at the name of the latest style to gain popularity among craft beer enthusiasts: the New England IPA. “None of the ingredients even come from New England,” Ocean says.