As the coronavirus has spread throughout the country, the need for personal protective equipment (PPE) has increased dramatically, particularly for doctors and nurses who are treating patients in hospitals. Unfortunately, a surge in patients has meant that many hospitals are facing a shortage of critical equipment such as masks.

In late March, New York Governor Andrew Cuomo publicly asked any companies and individuals who are capable of producing this equipment to do so. And when he did, the Ithaca College community jumped into action, on a scale both large and small.

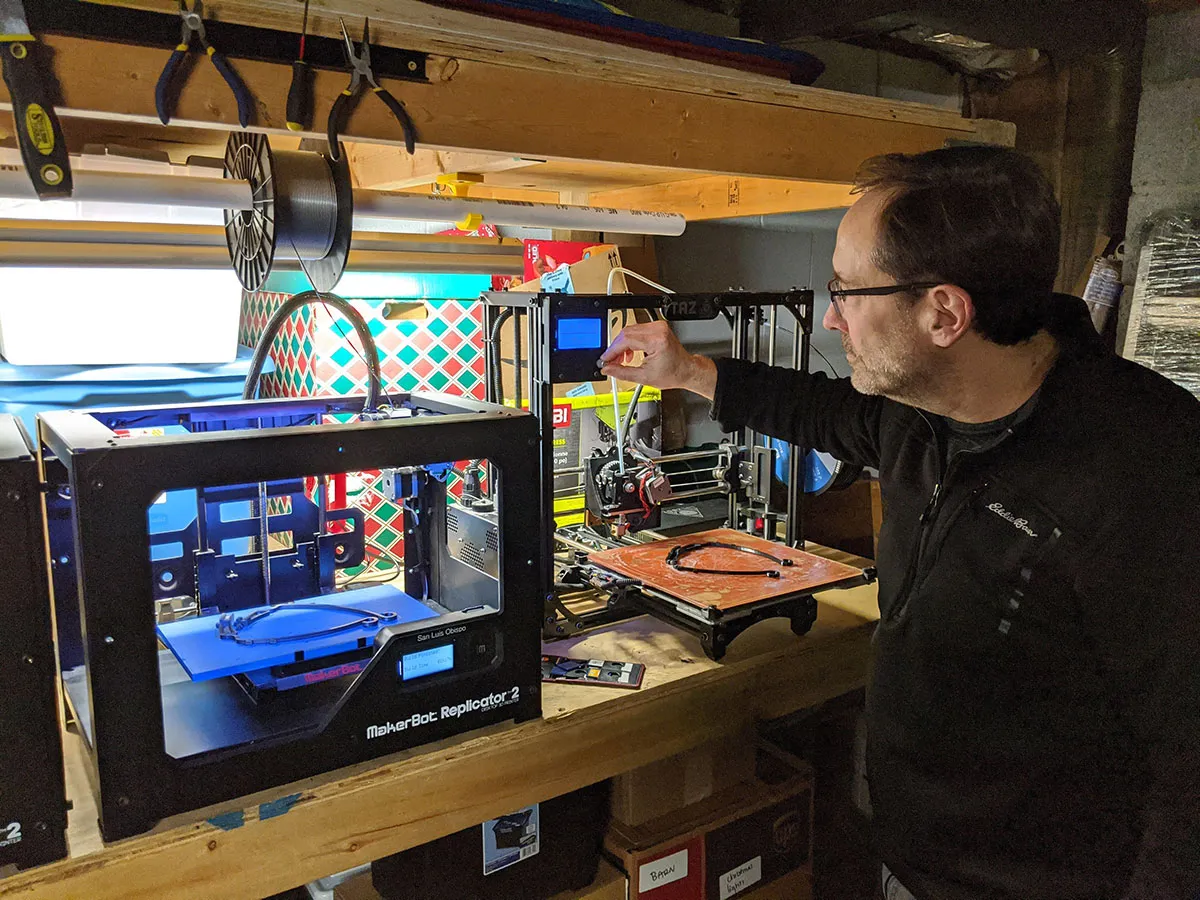

Jeff Golden is the director of general services at the college. Hearing Cuomo’s announcement, a light bulb went off. “It occurred to me, print operations manager Glen Harris and warehouse associate David Westgate that we were in a position to produce a lot of stuff pretty quickly,” he said. “So we talked with executive director of auxiliary services Dave Prunty about what we needed to do to get it up and running.”